How to select your perfect hinge blade

The needs of every bakery packing room are unique. That’s why we specialize in helping you find the hinge blade specs that suit you best, then making it right for you. Follow the steps below to identify your hinge blade needs and submit your request for quote. We’ll provide a quote within 24 business hours and, once approved, we’ll ship blades for next-day delivery.

Step 1

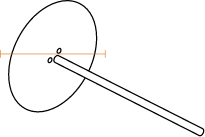

Choose Your Blade Diameter

We provide hinge blades in diameters ranging from 2.0 to 9.0 inches, with options at every 0.25 inch (for example 2.0″, 2.25″, 2.5″ 3.0″, etc.). To determine the diameter for your blade, measure the distance of the blade from edge to edge.

Step 2

Choose Your Stem Length

We offer stem lengths of any size. Standard sizes include: 4 ½”, 5 ½”, 8 ⅞“ (most popular), 9 ⅜” , 9 ½” and 9 ¾”.

Step 3

Choose Your Coating

The blade coating impacts durability, friction, lubrication, and overall performance for the specific use case. We offer the following coating options. If you have any questions about the best coating for your blade, our experts can help advise you.

None

Uncoated blades will be more affordable, but will lack the durability, anti-corrosion, and self-lubricating/non-stick benefits of coated blades.

Teflon™

Teflon™ offers long-lasting durability, non-stick, and low-friction properties through a unique blend of Teflon fluoropolymers, PTFE, FEP and PFA.

NEDOX®

NEDOX® increases surface hardness, prevents abrasive wear and galling, and provides a self-lubricating surface that resists corrosion and static buildup.

ARMOLOGY®

ARMOLOGY® TDC coating is 99% pure chromium and conforms precisely to the details in metal tool—resulting in a hard (78Rc), slippery, and corrosion-resistant surface.

Step 4

Choose Your Teeth Per Inch

The blade coating impacts durability, friction, lubrication, and overall performance for the specific use case. We offer the following coating options. If you have any questions about the best coating for your blade, our experts can help advise you.

10 Teeth per inch

(Standard)

32 Teeth per inch

(Fine Tooth)

Step 5

Choose Your Fastening Type

Rivets

(Standard)

Lock Nuts

(New, Patent Pending)

See What Makes LMC Blades The Best In The Industry

Our steadfast promise is to make it right, for you. Every hinge blade produced in our facility meets the absolute highest standards in materials and workmanship so that you can continue to meet the highest standards in your bakery. Get a quote to get started. Order a blade to see the difference in your business.

Best Materials

We are the only manufacturer to provide stainless steel shafts, #304 stainless. Our blades are laser-cut from chrome vanadium steel, and they are protected for storage and shipment with long-term corrosion inhibitors.

Superior, Anti-Wobble Machining

We use precision-ground shafts for a great fit into high-speed spindles—creating less vibration and longer life. To ensure perfect concentricity, we use a computer numeric controlled lathe to turn down the hub and the complete assembly.

Thorough Quality Check

Each blade is individually tested for runout on a lathe with an indicator. Total runout is guaranteed to be less than 10/1000 of an inch at a 3-inch diameter. (That’s about 2 hairs!)

Fast Delivery

Once an order has been placed, blades are shipped for next-day delivery so the blades you need are there when you need them.