Your choice of bakery equipment has a huge impact on the quality, taste and success of your bread and pastry products. So, it can be tempting to automate your operation with top-of-the-range bread slicers, bun baggers, and heat sealers.

But just because a machine is the most expensive, that doesn’t make it the best choice for you and your bakery. Instead, it’s important to consider your individual production needs, and choose the equipment that’s best suited to helping you reach your business goals.

It’s true that finding the right machinery can be fairly time-consuming. So, we’ve gone ahead and made a short bakery equipment quiz to help you find your perfect match in less than 60 seconds.

But if you want to know more about how to choose the right industrial bakery machinery, here are some major factors for you to consider.

What to consider when buying industrial bakery machinery

What range of products does your bakery sell?

First and foremost, your new machinery needs to match the products you bake. If you specialize in a single product, you’ll want machinery that’s tailor-made for that type of bread, cake or pastry. But if you offer a wide range of products, you’ll need the ability to quickly exchange blades, guides, and bags to keep up the pace of production.

As well as your current products, you might also want to think about any new items you want to sell in the future. That way, you know you’ll be prepared when the time comes to expand your offering.

How many loaves do you need to bake?

The ability to process 60 loaves a minute certainly sounds impressive. But unless your operation is set up to match it, then such a high-end capacity is just a wasted expense.

Before you start browsing for equipment, take some time to calculate your production rate. Then, choose a machine that’s well suited to your throughput to ensure you get the best value for money.

Just like with your range of products, you might also want to consider your bakery’s future growth, and choose a machine that can handle a slightly higher output. Then, you’ll be prepared to increase production when the time comes, as well as identify when you might want to upgrade your equipment again.

How much floor space does your bakery have?

When it comes to buying bakery machinery, there’s nothing worse than finding the perfect machine only to discover it doesn’t fit once it’s been delivered. Then, not only are you unable to install it, but you’re also stuck looking after an expensive machine that you need to return or sell on.

Be sure to double check your machine against your available floor space before you place an order. If it doesn’t fit with your current factory layout, consider whether you can rearrange your equipment to accommodate.

Does your chosen bakery machinery match your existing equipment?

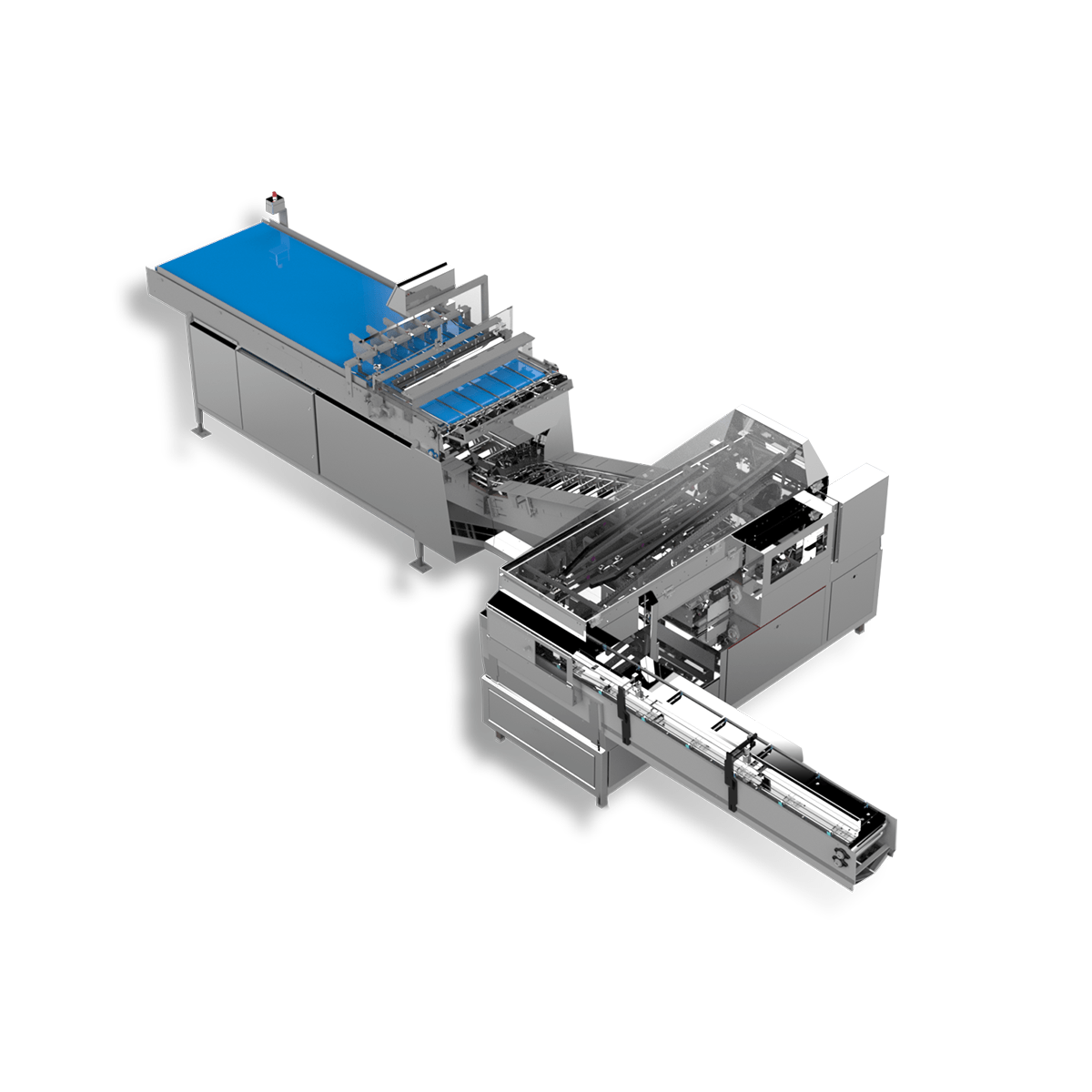

The key to quality baking is consistency. To make sure your products are mixed, processed, proofed, and baked to a high standard, your machinery needs to integrate seamlessly with your existing equipment.

However, with so many possible equipment combinations, that might be easier said than done. If you need expert advice on finding suitable machinery for your bakery, or to find out about custom solutions, please feel free to get in touch for a friendly chat.

Is your bakery machinery easy to clean and maintain?

Even after you find the perfect machine for your operation, it won’t stay in peak condition by itself. To ensure you can maintain optimal output, you should choose a machine that’s easy to dismantle for cleaning and maintenance.

As your machinery continues to transport, slice, and package your products, crumbs and debris get stuck in gaps and crevices. If this builds up, it can lead to bacterial growth and cross-contamination. So, it’s important to choose a machine with a hygienic design, as well as features like a removable crumb drawer, to allow for easy cleaning. This ability to dismantle your machine also helps with replacing worn or broken parts.

Similarly, it’s important to get your equipment professionally serviced and maintained about twice a year. This is useful for identifying and resolving possible risks before they can affect your production, leading to lower downtime and a longer machine lifespan. At LMC, our talented team of expert maintenance technicians provides a full range of maintenance and servicing solutions, helping you get the highest possible value from your equipment.

Should you buy new, used or refurbished bakery equipment?

Even though automating your bakery is a great way to boost your profitability, a lot of bakers worry about the expense. So, if you don’t have the budget for brand new equipment, consider buying used or refurbished equipment instead.

When selecting used industrial bakery equipment, remember to check the maintenance history, operating hours and which components are included. That will help you ensure a fair price, and confirm that the equipment still has plenty of life left. You might also want to partner with a custom manufacturing firm who can adjust your machinery to meet your precise needs.

Avoid machine downtime by stocking up on UBE replacement parts

Once you’ve found, purchased, and installed your ideal industrial bakery equipment, you’ll want to maintain the highest possible uptime and efficiency. A great way to do this is to keep a stock of replacement UBE parts like blades, brushes, rollers and spindles. That way, when a part becomes worn or breaks, you’re ready to replace it right away, and get your equipment up-and-running again.

To help you avoid machine downtime, LMC offers overnight delivery on our huge range of UBE replacement parts. What’s more, if you need a part that we don’t have in stock, we can custom manufacture it for you in only 24-hours.

Your one-stop-shop for industrial bakery machinery

Automating your bakery removes manual work and drastically increases production speed. From finding and installing equipment to comprehensive servicing and maintenance, LMC has everything you need to create a cohesive, fully integrated, fully automated bakery production line.

Contact us today, and we’ll guide you through your end-to-end bakery machinery experience.